Monochromator

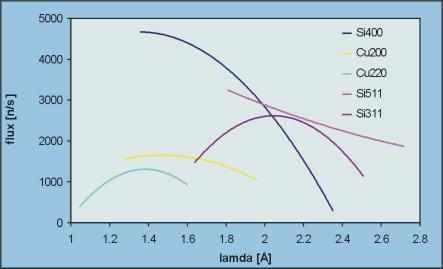

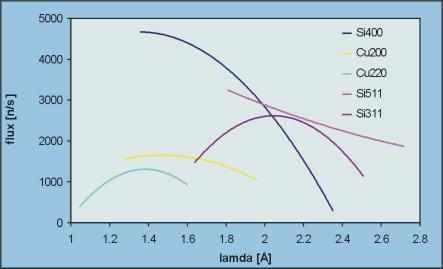

BT8 has three monochromators : Cu(220), Cu(200) and a double focusing Si(400). Because the (011) zone axis of the latter is

perpendicular to the plane of rotation, all permitted silicon reflections of the type  and

and  can be accessed by simply

rotating the monochromator. However, due to their intensity only Si(400), Si(311) and Si(511) are of interest (in this order).

For strain measurements, the optimal monochromator settings for each sample depend on the d-spacing of interest,

the desired 2θ

value and the intrinsic line width of the sample reflection (hkl). Besides the wavelength, the horizontal curvature of the

silicon monochromator is the other adjustable parameter which controls the Figure of Merit as the achievable accuracy of the

peak position per unit of counting time. If resolution is more important then the monochromator curvature can be optimized

down to a FWHM (Δd/d) of 3 10-3. Data collection times for strain measurements depend very much on the material.

For example,

to measure the Fe(211) or the Fe(011) peak with Δd/d=1 10-4 accuracy requires 4 min for a 1 mm3

sampling volume at 2θ=90º at

5 mm depth in reflection geometry. This assumes no intrinsic peak broadening and no preferred orientation.

can be accessed by simply

rotating the monochromator. However, due to their intensity only Si(400), Si(311) and Si(511) are of interest (in this order).

For strain measurements, the optimal monochromator settings for each sample depend on the d-spacing of interest,

the desired 2θ

value and the intrinsic line width of the sample reflection (hkl). Besides the wavelength, the horizontal curvature of the

silicon monochromator is the other adjustable parameter which controls the Figure of Merit as the achievable accuracy of the

peak position per unit of counting time. If resolution is more important then the monochromator curvature can be optimized

down to a FWHM (Δd/d) of 3 10-3. Data collection times for strain measurements depend very much on the material.

For example,

to measure the Fe(211) or the Fe(011) peak with Δd/d=1 10-4 accuracy requires 4 min for a 1 mm3

sampling volume at 2θ=90º at

5 mm depth in reflection geometry. This assumes no intrinsic peak broadening and no preferred orientation.

For aluminum

the counting time increases to more than 25 min. Routinely, measurements are conducted with an accuracy of

Δd/d=5 10-5

which requires four times the counting time. For practical purposes, the silicon monochromator with its (400) and (311)

reflections are superior to both copper crystals in all three parameters of interest: resolution, Figure of Merit and

intensity.

For aluminum

the counting time increases to more than 25 min. Routinely, measurements are conducted with an accuracy of

Δd/d=5 10-5

which requires four times the counting time. For practical purposes, the silicon monochromator with its (400) and (311)

reflections are superior to both copper crystals in all three parameters of interest: resolution, Figure of Merit and

intensity.

BT8 Home page

Ancillary Equipment

The Residual Stress Measurement Program

Last modified 03-April-2003 by website owner: NCNR (attn: )

and

can be accessed by simply rotating the monochromator. However, due to their intensity only Si(400), Si(311) and Si(511) are of interest (in this order). For strain measurements, the optimal monochromator settings for each sample depend on the d-spacing of interest, the desired 2θ value and the intrinsic line width of the sample reflection (hkl). Besides the wavelength, the horizontal curvature of the silicon monochromator is the other adjustable parameter which controls the Figure of Merit as the achievable accuracy of the peak position per unit of counting time. If resolution is more important then the monochromator curvature can be optimized down to a FWHM (Δd/d) of 3 10-3. Data collection times for strain measurements depend very much on the material. For example, to measure the Fe(211) or the Fe(011) peak with Δd/d=1 10-4 accuracy requires 4 min for a 1 mm3 sampling volume at 2θ=90º at 5 mm depth in reflection geometry. This assumes no intrinsic peak broadening and no preferred orientation.

For aluminum the counting time increases to more than 25 min. Routinely, measurements are conducted with an accuracy of Δd/d=5 10-5 which requires four times the counting time. For practical purposes, the silicon monochromator with its (400) and (311) reflections are superior to both copper crystals in all three parameters of interest: resolution, Figure of Merit and intensity.